Catalog excerpts

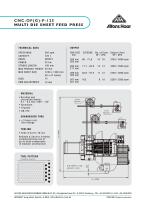

CNC-OF(G)-P-l25 MULTI DIE SHEET FEED PRESS A\fons Haar • Flexible press center for all types of ends and shells • Sheet and coil feed up to 16-out, 250spm • Material savings by utmost precision feed • Manpower savings by direct sheet processing eliminating strip shearing • AC-maindrive with static frequency converter including recuperation of flywheel brake energy • Die alignment system with electronic registering • Automatic central lubrication with closed circuit • Automatic pallet exchange system (optional) • Flexibility by shortest changeover times • Constant countersink depth by hydraulic compensator • Hydraulic overload safety device • Crankshaft roller bearings • Sheet length and angularity monitor • Playfree preloaded roller guidance of the ram

Open the catalog to page 1

CNC-OF(G)-P-l25 MULTI DIE SHEET FEED PRESS nitons Haar SEQUENCE OF OPERATION The sheets, scrolled or unscrolled, are destacked and fed to the prealignment station. On the way there is an optional rollertype sheet lubricator for double side or single side coating. Also the double sheet detection takes place there. The prealignment station corrects the alignment of sheets which are out of range because of unprecise packed stillages. According to the movement of the preceding sheets, the prealigned sheet is moved in the alignment station by a set of rollers driven by a servo motor. The...

Open the catalog to page 2

CNC-OF(G)-P-l25 MULTI DIE SHEET FEED PRESS titans Haar SHEET SQUARENESS MONITOR This system is equipped with a double set of dies, which requires a certain care for the first and the last punch of the sheet. These two punch positions are defined by cutting only one set of the die within the sheet. To avoid clipping out, it is required to make sure that the leading edge of the sheet does not touch the second die set. Additionally it is to guarantee, that the blank of the active die set is perpendicular. Especially if the sheet geometry is out of square (which is often the case) or if due to...

Open the catalog to page 3

Elions Haar CNC-OF(G)-P-l25 MULTI DIE SHEET FEED PRESS TECHNICAL DATA SPEED MAX: 250 spm DRIVE: DIRECT MAX PRODUCT HEIGHT: 20 mm MAX SHEET SIZE 1 250 x 1 200 mm OUTPUT END SIZE CUTEDGE No. of Tools Output 1/min mm OF / OFG OF / OFG MATERIAL • Scrolled and unscrolled sheets 0,1 - 0,5 mm /.004"- .02" • Aluminum • Tinplate • DR-TFS CHANGEOVER TIME • < 3 hours incl. Tool change TOOLING • Ends 9-out to 16-out Reliable & Service friendly uncompromising use of up-to-date-components in modular construction ALFONS HAAR MASCHINENBAU GMBH & CO. KG • Fangdieckstrasse 67 • D-22547 Hamburg • TEL +49 40...

Open the catalog to page 4All ALFONS HAAR MASCHINENBAU GMBH & CO. KG catalogs and technical brochures

-

COMPETENCE IN TOOL AND DIE

1 Pages

-

APPLICATIONS AND LINES

2 Pages

-

PRECISION FORM

2 Pages

-

ARU Aircraft Refuelling Unit

1 Pages

-

HIFR Assembly

2 Pages

-

MKA VANE METER

2 Pages

-

Helicopter Refuelling System

3 Pages