Catalog excerpts

Rev AC. 03/10/2017 Applies to AeroVee s/n 0440 and up. Includes top-mounted oil cooler. Photo for illustration only and does not represent the specific contents of your kit. A Product Line of Sonex Aircraft LLC

Open the catalog to page 1

AeroVee 2.1 Rev AC. 03/10/2017 Disclaimer and Limited Warranty The Experimental AeroVee Engine Kit is sold “as is”. No Warranty is expressed or implied! Sonex Aircraft LLC makes every effort to assure the supplied components of the AeroVee Engine Kit meet high quality and durability standards, and warrants to the original purchaser that these components are free of defects in material and workmanship for the period of one year from the date of purchase. This warranty does not apply to damage due directly or indirectly to improper assembly, misuse, abuse, negligence or accidents, repairs or...

Open the catalog to page 3

ASSEMBLY/SERVICE RESOURCES AeroConversions Resources AeroConversions continually improves and monitors its products. It is in your best interest to stay abreast of these improvements and implement them as needed. AeroConversions Website AeroConversions, Inc. maintains a website which is continuously updated. Perhaps the most important part of the website for an AeroVee builder/operator is the Service Bulletin section. You are encouraged to periodically check for Service Bulletins which may affect the performance of your AeroVee engine. The AeroConversion website is...

Open the catalog to page 4

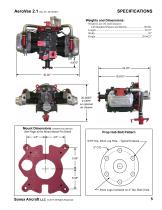

SPECIFICATIONS Weights and Dimensions: Mount Dimensions (Viewed from behind) See Page 40 for Motor Mount Pin Detail 4.8" Prop Hub Bolt Pattern 4.8" 9/16" Dia. Drive Lug Hole - Typical 6 places 5" O.D. Drive Lugs Centered on 4" Dia. Bolt Circle

Open the catalog to page 5

AeroVee 2.1 Rev AC. 03/10/2017 General Specifications (Subject to change without notice) Power and Displacement: SPECIFICATIONS Cylinder Identification, Engine Orientation, and Firing Order Cylinder Identification For assembly and maintenance, the AeroVee uses the cylinder identification numbers shown below. Engine Orientation When referencing the location / orientation of items on the engine, "Front", "Back", "Left", and "Right" are used as if the engine is installed in a tractor configuration and viewed from behind the engine, as shown below. Firing Order The AeroVee has a "wasted spark"...

Open the catalog to page 6

A Successful, Reliable Engine Installation Begins Here. Protect Yourself Always wear safety glasses When using paint and chemicals, work in a well ventilated room and wear appropriate protective gear (gloves, mask, etc.). The use of compressed air to clean parts is not recommended. Compressed air can send debris flying at great speed and cause serious injury. Do not use flammable liquids near open ignition sources such as water heaters, furnaces, electric motors, etc. Read, Understand, and Follow the Instructions Read through each procedure before performing the individual steps. Make sure...

Open the catalog to page 7

AeroVee 2.1 Rev AC. 03/10/2017 Note: If you have the optional pre-assembled crank shaft (part number ACV-H01-20), skip to Step 10. CRANKSHAFT ASSEMBLY Preparation: __ 1. Inspect the bore of the Crank Timing Gear for burrs. If necessary, lightly polish it with fine emery cloth. __ 2. Thoroughly clean all parts with Mineral Spirits. __ 3. Remove the four (4) hex plugs from the crankshaft and thoroughly clean the crankshaft with Mineral Spirits. Re-install the hex plugs with Locktite #242. __ 4. Test fit the prop hub. The prop hub should NOT slide onto the crankshaft. __ 5. Place the cleaned...

Open the catalog to page 8

CRANKSHAFT ASSEMBLY __ 3. Install the Timing Gear with the two machined dots (arrow in photo) facing away from bearing #2. __9. Align the keyway of the Prop Hub with the forward woodruff key installed in the crankshaft and tap the prop hub into place using a mallet and block of wood. The prop hub must be tight against the oil slinger. __ 4. Install the Retaining Ring in the groove in the crank. Immediately install Prop Hub Bushing and Washer and Bolt (ACV-Z01-74). Use an impact wrench to tighten the bolt and push the prop hub against the oil slinger. __ 5. Enlarge the oil supply hole in...

Open the catalog to page 9

AeroVee 2.1 Rev AC. 03/10/2017 Tools Required: __ Socket Wrench __ 13mm Socket __ Torque Wrench (20 ft.-lbs. capacity) __ "Red" Locktite (High Strength Threadlocker) Parts Required: __ Cam Gear, ACV-P01-49 __ Cam Shaft (w/ hardware), ACV-P01-72 CAM ASSEMBLY __1. Align the machined dot on the face of the Cam Gear (arrow in photo) with the slot in the Cam Shaft. Apply Red Locktite to the bolts and install the bolts and washers (if provided). __2. Torque the bolts to 20 ft-lbs. Assembly Instructions: Note: The Assembly Lube provided with the cam gear will be used to lubricate the valve lifters...

Open the catalog to page 10

Tools Required: __ White Lithium Grease __ Socket Wrench and Socket Set __ Moly Lube __ Torque Wrench (40 ft-lbs. capacity) __ Feeler Gauge __4. The connecting rods are installed on the crankshaft with the bearing anti-rotation notches at the bottom of the crank. Re-assemble the connecting rods as matched parts. 4 Parts Required: __ Connecting Rods, ACV-P06-33 __ Rod Bearing Set, ACV-P01-59 __ Crankshaft Assembly Assembly Instructions: Note: Both parts of each connecting rod are marked with a unique number, identifying them as matched parts. The connecting rods must be reassembled as...

Open the catalog to page 11

CRANK CASE PREPARATION Assembly Instructions: __1. Install the head studs as shown in the photos below. Tools Required: __ Flat Blade Screwdriver __ Rubber Mallet __ Fine File __ White Lithium Grease Cylinder Head Stud Placement S = Short Cylinder Head Stud (7-3/8" - 7-1/2" long) Parts Required: __ Engine Case __ 8mm Head Stud Kit, ACV-P01-86 __ Case kit, ACV-P02-12 __ Main Bearing Dowel Pins (Set of 5), ACV-P01-46 __ Valve Lifters, ACV-P01-48 __ Main Bearing Set (split bearings only), ACV-P01-57 __ Cam Bearings, ACV-P01-58 __ Gasket Set, ACV-P02-15 M = Medium Cylinder Head Stud (8" -...

Open the catalog to page 12

AeroVee 2.1 Rev AC. 03/10/2017 __2. Lay the case on it's side so the oil pressure relief ports in the bottom of the case are accessible. 2 Oil Pressure Relief Ports CRANK CASE PREPARATION __8. Insert the short spring behind the non-grooved plunger. __9. Place a metal gasket on a retaining plug and screw the plug into the relief port. __10. Install the Main Bearing Stud Seals (Qty. 6) from the Gasket Set (ACV-P02-15). The seals slide over the 6 large studs in the right case half. 10 __3. Find the oil pressure relief plungers (2), springs (1 long, 1 short), metal gaskets (2) and retaining...

Open the catalog to page 13All AeroConversions catalogs and technical brochures

-

AeroVee Turbo

33 Pages