カタログの抜粋

SECO NEWS 2019.1 JETI CONVERSION GROOVING & PARTING-OFF 1 Copyright © 2018 Seco Tools AB

カタログの1ページ目を開く

SAFETY FIRST Emergency Exit Emergency Number Assembly Point Protective Equipment Copyright © 2018 Seco Tools AB

カタログの2ページ目を開く

3 Copyright © 2018 Seco Tools AB Complicated and timeconsuming tool exchanges Frequent machine stoppages Poor machining performance Short tool life Common Customer Challenges Low-quality parts Unreliable processes

カタログの3ページ目を開く

■ Deep cuts —► difficult for coolant to reach cutting zone ■ Challenging materials —► high temperature in the cutting zone ■ Long, difficult-to-remove chips prevent efficient cooling, reduce tool life, affect part quality and increase machine down-time ■ External coolant-delivery equipment interferes during machining ■ Time-consuming tool change 4 Copyright © 2018 Seco Tools AB SECO I

カタログの4ページ目を開く

Improves performance and tool life Stabilizes processes Eliminates long chips Reduces down-time Simplifies tool change process Eliminate limitations caused by external piping 5 Copyright © 2018 Seco Tools AB SECO I

カタログの5ページ目を開く

6 Copyright © 2018 Seco Tools AB SECO I

カタログの6ページ目を開く

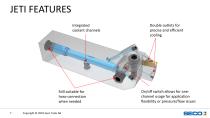

JETI FEATURES Integrated coolant channels Still suitable for hose connection when needed 7 Copyright © 2018 Seco Tools AB Double outlets for precise and efficient cooling On/off switch allows for onechannel usage for application flexibility or pressure/flow issues

カタログの7ページ目を開く

Copyright © 2018 Seco Tools AB

カタログの8ページ目を開く

JETI: A FLEXIBLE PROBLEM SOLVER User-friendly hoseless connection Complicated and timeconsuming tool exchanges Fewer extra spare parts Short tool life Common Customer Challenges Frequent machine stoppages Excellent chip control Copyright © 2018 Seco Tools AB Precise, efficient high-pressure cutting edge cooling Poor machining performance Low-quality parts Unreliable processes Optimized coolant delivery for wider range of applications with Duo/Single JETI

カタログの9ページ目を開く

■ MDT Jetstream Tooling® holders with shank sizes 20 x 20 mm or 25 x 25 mm and insert pocket seat sizes from 2 to 8 mm, both radial and axial - 182 items ■ X4 holders with shank sizes 20 x 20 mm or 25 x 25 mm - 4 items ■ 150.10 holders for 15-size blades and with shank sizes 20 x 20 mm or 25 x 25 mm - 4 items 10 Copyright © 2018 Seco Tools AB SECO I

カタログの10ページ目を開く

Copyright © 2018 Seco Tools AB

カタログの11ページ目を開く

PRODUCT RANGE ADAPTERS For available shank adapters – Seco-Capto, HSK-T, VDI – see My Pages

カタログの12ページ目を開く

JETI SUMMARY Precise, fully integrated coolant delivery r?\ Improved performance provides new opportunities for optimization Reduced production costs

カタログの13ページ目を開くSECO TOOLSのすべてのカタログと技術パンフレット

-

Solid End Mills.pdf

641 ページ

-

DOUBLE OCTOMILL™

2 ページ

-

PRODUCT SUMMARY

2 ページ

-

SECO NEWS SUMMARY 2018.1

14 ページ

-

POZVÁNKA ZD KOVOSVIT

1 ページ

-

Machinability_poster

1 ページ

-

SQUARE T4

2 ページ

-

SECO Product summary

2 ページ

-

SECO NEWS

310 ページ

-

DURATOMICTM

16 ページ

-

QUATTROMILL-AL™

2 ページ

カタログアーカイブ

-

DISC MILLING

36 ページ