カタログの抜粋

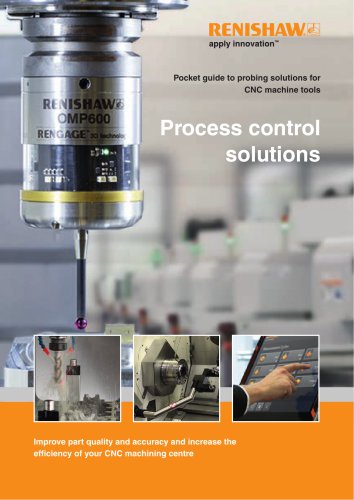

RENISHAW. apply innovation™ Probing systems for CNC machine tools

カタログの1ページ目を開く

© 2001 - 2014 Renishaw pic. All rights reserved. This document may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any means, without the prior written permission of Renishaw plc. The publication of material within this document does not imply freedom from the patent rights of Renishaw plc. Trade marks RENISHAW and the probe symbol used in the RENISHAW logo are registered trade marks of Renishaw plc in the United Kingdom and other countries. apply innovation and names and designations of other Renishaw products and technologies are trade...

カタログの2ページ目を開く

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 How and where probes are used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Why probe?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 How a probe works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 The Productive Process Pyramid™ . . . . . . . . . . . . . . . ....

カタログの3ページ目を開く

Job contact probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38 RENGAGE™ strain gauge probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40 OMP400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40 MP700. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42 RMP600. . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

カタログの4ページ目を開く

Measurement and inspection software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 Spindle probing software functionality comparison chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 Software overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 Software compatibility selector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 EasyProbe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

カタログの5ページ目を開く

OMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8 OSI and OMM-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10 MI 12 / MI 12-B and OMM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12 Optical performance envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14 RMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

カタログの6ページ目を開く

How and where probes are used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Why probe?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 How a probe works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 The Productive Process Pyramid™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6 Process foundation. . . . . . . . . . . . . . . . . . . . . . ....

カタログの7ページ目を開く

Probing systems for CNC machine tools Renishaw invented the touch-trigger probe in 1973, revolutionising the capabilities of co-ordinate measuring machines (CMMs) and enabling them to become the industry standard for offline 3D component inspection. Machine tool users have benefitted from the use of probes since the mid 1970s. Automated probing for set-up and in-cycle inspection became possible in the 1980s when Renishaw introduced the first probes designed specifically for metal cutting applications. How and where probes are used Today, probing is an established best practice for...

カタログの8ページ目を開く

apply innovation™ Time is money, and unnecessary time spent manually setting workpiece positions and inspecting finished products will impact on your manufacturing performance and profitability. Renishaw probing systems eliminate costly machine down-time and the scrapping of components associated with manual setting and inspection. Increase throughput from your existing assets If your machines are overloaded then you could face a sizeable capital investment to make up the shortfall, or a large sub-contract bill. Or worse still, you might find yourself turning away profitable work. But what...

カタログの9ページ目を開く

Probing systems for CNC machine tools How a probe works Machine mounted probes are often referred to as touch-trigger probes because they use switches that are triggered upon contact between the probe’s stylus and the component being measured or set. Switching is highly repeatable. When triggered, the probe signals the control via an interface and the control (almost simultaneously) automatically captures the machine tool position via its encoders (feedback system). Machine spindle mounted probe Wireless interface Circle (3 points) Point With a co-ordinate point captured, the probe moves on...

カタログの10ページ目を開く

Machine tool applications and Renishaw products Cutting machine tools fall into the following broad categories: • Manually operated Controlled – computer numerical control (CNC) Most machine tools used in the production environment today are CNC machines and these can be further categorised into: • • Lathes for turning round parts Multi-tasking (mill–turn) machines that combine processes Grinding machines for fine finishing Machining centres for milling, drilling and tapping prismatic parts Drilling and routing machines for PCBs Diverse application Machine tool variety is significant with...

カタログの11ページ目を開くRenishaw PLCのすべてのカタログと技術パンフレット

-

AxiSet Check-Up

12 ページ

カタログアーカイブ

-

Vacuum casting systems

16 ページ

-

Styli and accessories

120 ページ