カタログの抜粋

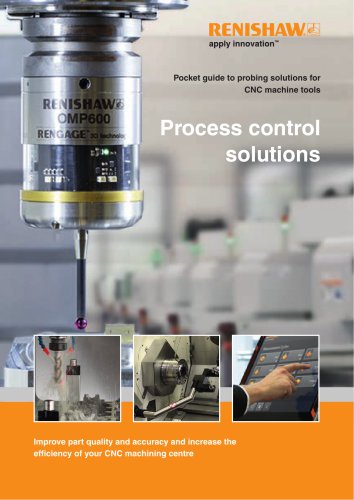

Pocket guide to probing solutions for CNC machine tools Process control solutions Improve part quality and accuracy and increase the efficiency of your CNC machining centre

カタログの1ページ目を開く

CNC machine tool probing solutions … Renishaw’s range of process control solutions provides a systematic approach to eliminating variation at all stages of your machining process, backed by innovative technology, proven methods and expert support. This pocket guide provides an overview of Renishaw’s solutions for CNC machine tools and the benefits that these can bring to your manufacturing business. Renishaw profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Why probe?. . . . . . . . . . . . . . . . . . . . . . . . ....

カタログの2ページ目を開く

apply innovation" Renishaw profile Why choose Renishaw? We offer a comprehensive suite of metrology, advanced manufacturing and process control solutions to enable manufacturers to maximise their productivity and achieve the capabilities they need A world leader in engineering technologies, Renishaw applies its core skills in measurement and precision machining to sectors as diverse as dimensional metrology, spectroscopy, machine calibration, motion control, dentistry and surgical robotics Solutions for industrial metrology and manufacturing Our sensors for co-ordinate measuring machines...

カタログの3ページ目を開く

apply innovation" Why Probe? Time is money, and time spent manually setting workpiece positions and inspecting finished products will impact on your manufacturing performance and profitability. Renishaw probing systems eliminate this costly machine down-time and associated scrapping of components Increase throughput from your existing assets If your machines are overloaded, you could face a sizeable capital investment to make up the shortfall, a large sub-contract bill, or worse still, turn away profitable work But what if you could extract more throughput from your existing machinery? You...

カタログの4ページ目を開く

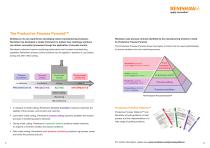

The Productive Process Pyramid™ Building on its own experiences developing robust manufacturing processes, Renishaw has developed a simple framework to explain how metrology solutions can deliver successful processes through the application of process control. Renishaw’s solutions improve machining performance and increase manufacturing capability. Renishaw’s process control solutions can be applied in advance of, just before, during and after metal cutting. Renishaw uses process controls identified by the manufacturing timeline to build its Productive Process Pyramid. The Productive...

カタログの5ページ目を開く

Informative controls applied after machining is complete Process foundation Active controls applied during metal cutting Predictive controls applied just before cutting Preventative controls applied in advance Postprocess monitoring In-process control Process setting Informative controls applied after machining is complete Process setting Active controls applied during metal cutting Predictive controls applied just before cutting Preventative controls Process foundation Postprocess monitoring In-process control Process setting Process foundation Controls in the base layer of the Pyramid are...

カタログの6ページ目を開く

Informative controls applied after machining is complete In-process control Active controls applied during metal cutting Predictive controls applied just before cutting Preventative controls applied in advance Postprocess monitoring In-process control Process setting Informative controls applied after machining is complete Post-process monitoring Active controls applied during metal cutting Predictive controls applied just before cutting Preventative controls Process foundation Postprocess monitoring In-process control Process setting Process foundation Controls in this Pyramid layer...

カタログの7ページ目を開く

apply innovation” Product application guide to your application Identify which machine tool probes are suited11 *Table sizes

カタログの8ページ目を開く

apply innovation" Industry-leading technology and performance Breakthrough solutions are at the heart of Renishaw's business strategy, which is captured by the phrase ‘apply innovation’. The innovative product design is a result of unparalleled investment into R&D, allowing Renishaw to offer you market leading solutior to help your business . Modulated optical transmission is used for all new generation 'OMP' probes, providing the highest level of resistance to light interference Frequency hopping spread spectrum (FHS is a unique transmission system that does not use a dedicated...

カタログの9ページ目を開く

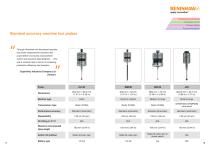

Post-process monitoring In-process control Process setting Process foundation Standard accuracy machine tool probes Previously it could take 1.5 hours to set a job that took 4.5 hours of machining; that was totally unacceptable. Now we can do the same set-up in 10 minutes, immediately freeing up 1 hour 20 minutes to cut more metal, which we make money on. J J Sewtec Automation (United Kingdom) 040 mm x 58.3 mm (1. 57 in x 2.30 in) Lathe Infrared (optical) Standard (kinematic) 1. 00 pm (40 pin) N/A Optical M-code; auto start 063 mm x 76 mm (2.48 in x 2.99 in) Medium to large Infrared...

カタログの10ページ目を開く

Standard accuracy machine tool probes // Through Renishaw we discovered machine tool probe measurement solutions that could deliver in-process measurement control and real-time data feedback ... This was a massive help in terms of increasing production efficiency and precision. SuperAlloy Industrial Company Ltd (Taiwan) Probe Dimensions Machine type 040 mm x 58.3 mm (1. 57 in x 2.30 in) Lathe Transmission type Radio (FHSS) Performance accuracy Repeatability 3D lobing in X Y Z Maximum recommended stylus length Switch ON method Radio M-code; spin Battery type 040 mm x 50 mm (1 57 in x 1...

カタログの11ページ目を開く

High accuracy machine tool probes // We are very happy with the accuracy of RMP600 and, in particular, the consequent reduction in scrap parts further down the production line. These are large expensive components and we use the probe to identify and avoid errors. Tods Composite Solutions (United Kingdom) // Probe Dimensions Machine type Transmission type Performance accuracy Repeatability 3D lobing in X Y Z Maximum recommended stylus length Switch ON method Battery type 040 mm x 50 mm (1. 57 in x 1. 97 in) Small to medium Infrared (optical) High (strain gauge) 0.25 pm (10 pin) ±1. 00 pm...

カタログの12ページ目を開くRenishaw PLCのすべてのカタログと技術パンフレット

-

Vacuum casting systems

16 ページ

-

Styli and accessories

120 ページ

-

AxiSet Check-Up

6 ページ