カタログの抜粋

Aerospace Taking Risk and Cost out of your Business Tooling Solutions from EMUGE-FRANKEN

カタログの1ページ目を開く

Aerospace Components MUCEFRANKEN Engine Components and Accessories • Blades / Blisks • Disks / Shafts / Hubs Landing Gear Components • Main landing gear beam • Landing gear components

カタログの2ページ目を開く

Aerospace Components £MUCE FRANKEN Structural Components • Spars / Skins / Ribs / Frames • Pylons • Flap tracks • Other components From light weight structure composite materials to advanced super alloys, EMUGE-FRANKEN has the know-how, the engineers, the application expertise and last but not least the tools to reduce risks and costs in the manufacture of aerospace programmes. We partner with our customers to develop machining strategies and to implement standard and customised solutions with minimum cost per part and high repeatability in mind.

カタログの3ページ目を開く

FRANKEN Product Lines for Aerospace Programmes

カタログの4ページ目を開く

MUCE FRANKEN End mills Product lines that drive your productivity £MUCE £muce runuun EF-Drill-VA blueCUT

カタログの5ページ目を開く

FRANKEN Clamping Tool Technology Features: • Outer dimensions: • Clamping force: • Transmittable torque: • Clamping diameter: • Weight: Features: • Outer dimensions: • Clamping force: • Transmittable torque: • Clamping diameter: • Weight:

カタログの6ページ目を開く

Threading Technology – Thread Milling Whatever thread milling solution you are looking for, we have it! Huge portfolio of standard tooling • All thread systems • Huge variety of construction sizes • Applicable in all materials Solid carbide thread milling cutters, variable • With corrected thread profile (for different thread sizes, but for one pitch only) • Increased number of flutes • Optimised cutting geometry Solid carbide circular thread milling cutters • With corrected thread profile (for one single thread size only) Solid carbide thread milling cutters with countersinking step • For...

カタログの7ページ目を開く

FRANKEN Threading Technology - Taps The best tap only works properly, when using it with the right holder. EMUGE-FRANKEN is a globally leading supplier of high precision, high performance taps with nearly 100 years of knowledge in designing, manufacturing and applying the tools. • Huge standard portfolio for all thread systems • Wide range of product lines for all kind of materials • Innovative and optimised geometries for various applications • Advanced in-house coating technology • Design and manufacturing of corresponding holders EMUGE-FRANKEN develops and manufactures holders for any...

カタログの8ページ目を開く

Threading Technology - Taps MUCE FRANKEN Product lines for all common aerospace materials - overview of our standard geometries with brief description Besides taps and holders, we also manufacture corresponding gauges. DECOM UGK is a DAkkS-accredited test laboratory for length and other Our cooperation partner DECOM UGK located on the EMUGE premises is geometrical measuring parameters. available for the calibration of your gauging and measuring equipment.

カタログの9ページ目を開く

Milling Technology Machining time reduction in finishing by up to 90% with circle segment end mills. Circle segment end mills can work with considerably larger axial feeds compared to traditional ball-nose cutters. Due to the large radius on the circumferential cutting edge of the barrel cutter, it theoretically equals a ball-nose cutter with a diameter of 150-500 mm or even larger. axial feed of 0.2 to 0.5 mm during the finishing process, the barrel cutter provides five-times these axial feeds while still achieving the desired surface quality. In theory you use a carbide ball-nose cutter...

カタログの10ページ目を開く

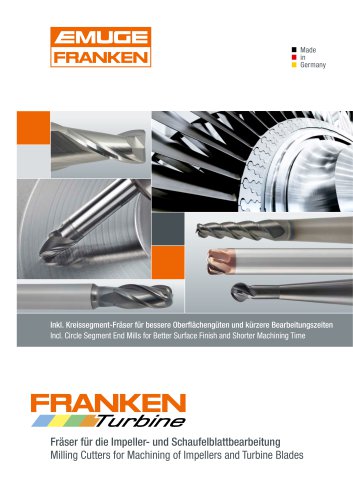

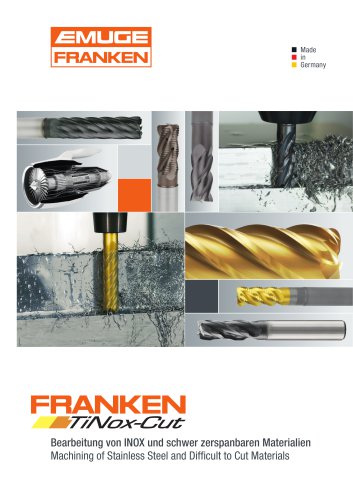

Turbine tools with specially tailored geometry were developed for the requirements of materials and component designs in the aircraft and turbine industry. Characteristics: • Stable design due to taper design • Newly developed geometry for machining aluminium • Highly heat-resistant coating • Roughing and semi-finishing profiles available Standard Milling programme for difficult to cut materials (Titanium, Nickel-base alloys)

カタログの11ページ目を開く

FRANKEN Twist Drills Specially designed for machining austenitic, stainless steels. These twist drills are available in the designs according DIN 6537 short (3 x D) and EMUCE long (5 x D) from stock. EF-Drill-VA They are also suitable for use in special materials like titanium alloys, nickel alloys, cobalt alloys and iron alloys. FRANKEN /=/jbe/^-Cis£ EMUCE EF-Drill-AL EF-Drill-GAL MUCE EF-Drill-NI Fiber-Cut Drill is specially designed for drilling CFK. Multiple layered or structural layered carbon fibres will be cut without delaminating the layers. The diamond coating slows down tool wear,...

カタログの12ページ目を開く

Company NAWA GmbH is the PCD milling expert within the EMUGE-FRANKEN group. Thanks to a diverse machine tool outfit, NAWA is able to produce unique tooling in outstanding quality in a short period of time. Besides a standard tool portfolio, NAWA is spezialised in designing and manufacturing of custom solutions. blueCUT The NAWA blueCUT end mill is a proven milling solution for machining of composite materials and aluminium: • Durable PCD grade for long tool life • Precise run out, to keep tight work piece tolerances • Excellent edge preparation for a clean cut without fraying • Standard...

カタログの13ページ目を開く

FRANKEN Technical Customer Support Our application engineering specialists are at your disposal worldwide. On request we implement new concepts and offer support for the optimisation of your production processes. We test your materials in our test workshop and recommend the optimal tool. We will develop and design special tools specifically for your needs. Our service also includes system solutions. The close cooperation of our OEM team with the manufacturers of machines provides us with a comprehensive insight into process parameters. As a result we can develop and implement the most...

カタログの14ページ目を開く

Technical Customer Support We do not only cooperate with machine tool manufacturers, but we also maintain close relationships with leading CAD-CAM suppliers to be able to set up the process to fully utilise the machine tool the CAM capabilities. This way we are able to design and suggest the most efficient and reliable manufacturing concept for lowest cost per part and highest process reliability. Example for process design for a manufacturer of aerospace components Product lines that drive your productivity Custom solution Custom solution

カタログの15ページ目を開くEMUGE-Werk Richard Glimpel GmbH & Co. KGのすべてのカタログと技術パンフレット

-

FIBER-cut

28 ページ

-

Expert

32 ページ

-

Turbine

52 ページ

-

TiNox-Cut

40 ページ

-

ZGF

24 ページ

-

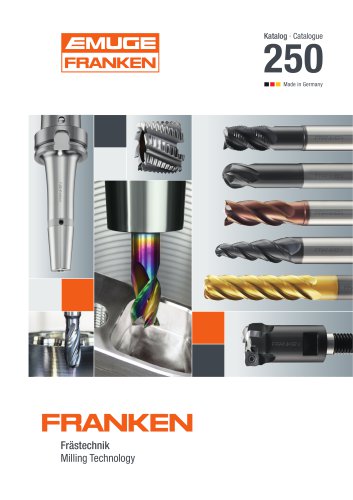

Catalogue 250

440 ページ

-

Catalogue 156

92 ページ

-

NAWA

12 ページ

-

NAWA Modular

4 ページ

-

Catalogue 154

104 ページ

-

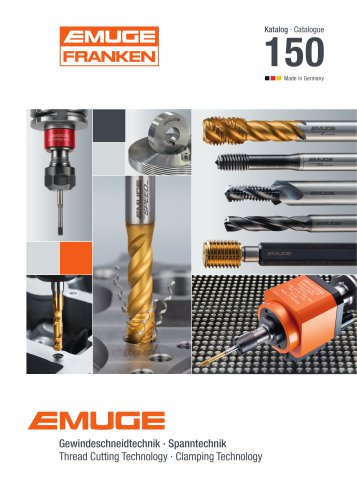

Catalogue 150

872 ページ

-

CATALOG 520

672 ページ

-

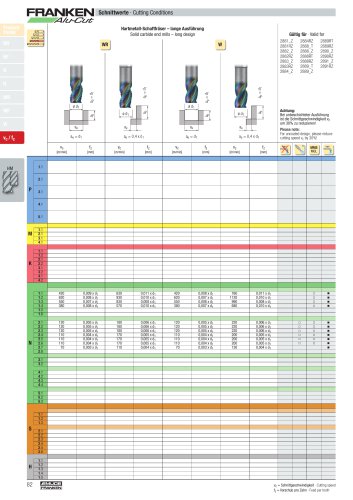

Cutting Conditions

1 ページ