カタログの抜粋

No.6, 2nd Nanyun Road, Science City, Hi-tech Development Zone, Guangzhou, 510663, P.R.C 2024 Conprofe Technology Group Co., Ltd. All Rights Reserved. VE2.6 The information given is not binding. Actual products and mutual agreement shall prevail. Reprinting of any text and illustrations requires written authorization of Conprofe.

カタログの1ページ目を開く

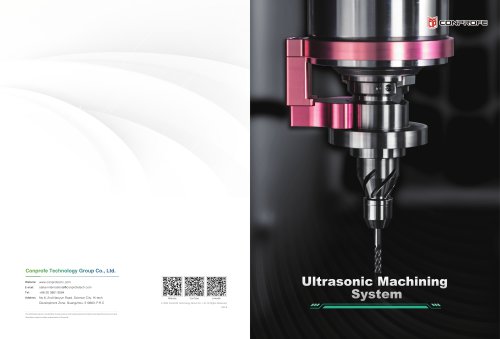

Ultrasonic Working Principle Applicable Materials Unique Machining Advantages ················· 06 Ultrasonic Engraving and ················· 07 Millin

カタログの2ページ目を開く

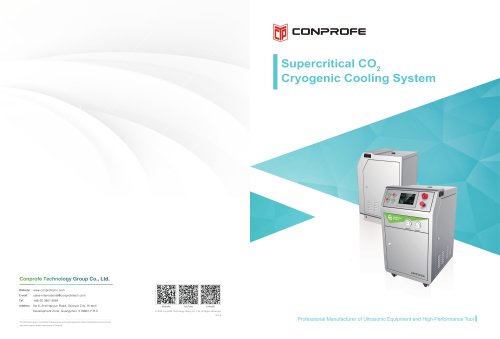

erging of Global Resources Prafe ssional as Industry Leader With its roots back to 2003, Conprofe is a Provider of Efficient, Green and Intelligent Manufacturing Solutions and Key Units. It has been holding on to the idea of “Converging of Global Resources, Professional as Industry Leader” in the past two decades. Revolving around “Efficient, Green and Intelligent Manufacturing”, the company has achieved a giant leap from parts, units to machines and developed a product portfolio with three major industries - Precision Tools, Key Units and CNC Machine Tools, which covers eight categories of...

カタログの3ページ目を開く

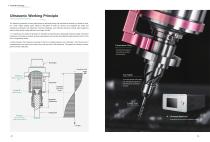

Ultrasonic Working Principle ^-V The ultrasonic generator converts high-frequency electrical energy into mechanical vibration by ultrasonic vibration, which makes rotating cutter vibrate at thousands of times per second, and separates the cutter and workpiece periodically, thus effectively removing chippings, and indirectly improving cooling effect leading to better surface quality, higher efficiency and longer tool life. 1. In machining, the ultrasonic generator is activated by high-frequency alternating electrical energy, driving the transducer to resonate as a whole. Energy is generated...

カタログの4ページ目を開く

Applicable Materials Hard-Brittle Materials Materials﹣ Single-Crystle Silicon, Aluminium Oxide, Sapphire, Glass, Sillicon Nitride, AISiC, etc. Workpiece﹣ Semiconductor Showerhead, Speculum, Optical Fiber Stick, Mobile Phone Cover, Watch Dial Plate, Graphite Mold, Denture, etc. Ultrasonic Machining Advantages Composite Materials Materials﹣ Nomex Honeycomb, Carbon Fiber, Carbon Fiber Reinforced Metal Composites, etc. Workpiece﹣ Spacecraft Component, Automobile Lightweight, Railway Transit Component, etc. Hard-to-Cut Metals Materials﹣ Stainless Steel, Titanium Alloy, Superally, etc. Workpiece﹣...

カタログの5ページ目を開く

HBK^E25 Ultrasonic Tool Holder Ultrasonic Milling/ Grinding >• Specification ► Drawing and Dimensions (unit: mm) Item HSK-E25 Working Frequency 16-70kHZ Auto Tool Change Standard ► Specification ► Drawing and Dimensions (unit: mm) Auto Tool change Standard Coolant-Through Spindle Optional Working Frequency Collet Model Clamping Accuracy Spindle Taper Coolant-Through Spindle

カタログの6ページ目を開く

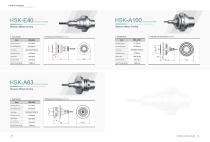

Ultrasonic Tool Holder Ultrasonic Milling/ Grinding HWfAlOO Ultrasonic Tool Holder Ultrasonic Milling/ Grinding > Specification > Drawing and Dimensions (unit: mm) >■ Drawing and Dimensions (unit: mm) Item HSK-E40 Item HSK-A100 Working Frequency 16-70 kHz Auto Tool change Standard Auto Tool change Standard Coolant-Through Spindle Optional Coolant-Through Spindle Optional HMKtfA63 Ultrasonic Tool Holder Ultrasonic Milling/ Grinding ► Specification Item HSK-A63 ► Drawing and Dimensions (unit: mm) Auto Tool change Standard Coolant-Through Spindle Optional All Models Could Be Customized 10

カタログの7ページ目を開く

ISO20 Ultrasonic Tool Holder Ultrasonic Milling/ Grinding Item ISO20 Working Frequency -| 6-70kHz Auto Tool change Standard IS025 Ultrasonic Tool Holder Ultrasonic Milling/ Grinding Item IOS25 Working Frequency 16-70kHz Auto Tool Change Standard Coolant-Through Spindle Optional ► Drawing and Dimensions (unit: mm) All Models Could Be Customized 12

カタログの8ページ目を開く

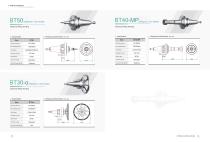

BT30 Ultrasonic Tool Holder Ultrasonic Milling/ Grinding ► Specification Item BT30 Collet Model SK06/SK10/SK16 Clamping Accuracy 0.008mm Auto Tool Change Standard Coolant-Through Spindle Optional BT40 ► Drawing and Dimensions (unit: mm) Ultrasonic Tool Holder Ultrasonic Milling/ Grinding > Specification Item BT40 Working Frequency 16-70kHZ Collet Model SK06/SK10/SK16 Clamping Accuracy 0.008mm Auto Tool Change Standard Coolant-Through Spindle Optional ► Drawing and Dimensions (unit: mm) 13 All Models Could Be Customized 14

カタログの9ページ目を開く

BT50 Ultrasonic Tool Holder Ultrasonic Milling/ Grinding BT40-MP Ultrasonic Tool Holder Ultrasonic Milling/ Grinding >• Drawing and Dimensions (unit: mm) Auto Tool change Standard coiiet Model Customized Auto Tool change Standard Coolant-Through Spindle Optional Coolant-Through Spindle Optional Ultrasonic Tool Holder Ultrasonic Milling/ Grinding >• Drawing and Dimensions (unit: mm) coiiet Model Customized Auto Tool change Standard All Models Could Be Customized 16

カタログの10ページ目を開く

Ultrasonic Tool Holder Ultrasonic Cutting coiiet Model Customized Auto Tool Change Standard Ultrasonic Cutting ► Drawing and Dimensions (unit: mm) Ultrasonic Tool Holder coiiet Model Customized Auto Tool change Standard All Models Could Be Customized 18

カタログの11ページ目を開く

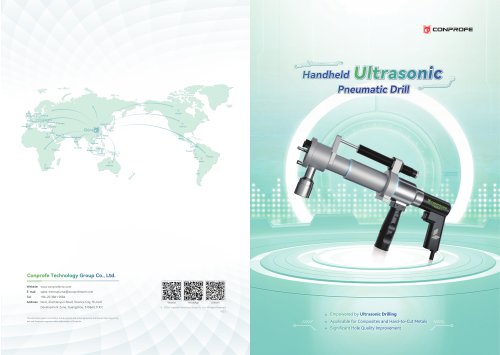

Ultrasonic Turning► Features 1. Significant cutting force reduction 2. Less chipping, burrs, build-up edges and less workpiece distortion 3. Stable machining and effective chatter elimination 4. Cooling and lubricating improvement of cutting fluid 5. Tool life improved by up to dozens of times All Models Could Be Customized 20

カタログの12ページ目を開くConprofe Technology Group Co.のすべてのカタログと技術パンフレット

-

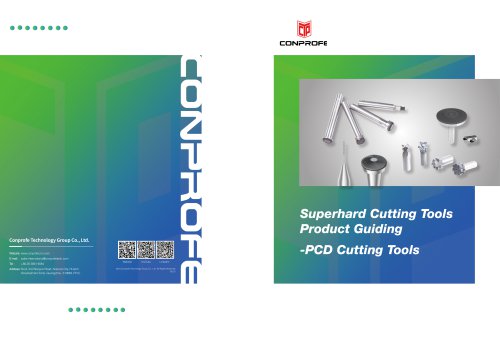

PCD Cutting Tools

14 ページ

-

Tapping Tools

38 ページ