Estratti del catalogo

Stainless Steel High Performance End Mills

Aprire il catalogo a pagina 1

Using the latest in engineering design and grinding capabilities, the new Series 33 High Performance End Mills handle slotting of difficult materials such as Stainless Steel, Titanium, and Inconel. Ideal for applications struggling with chip evacuation, this 3-Flute design offers increased chip clearance and a reduction in harmonics. • Unique 3-Flute design provides more controlled and manageable chip formation. • ngineered stepped core configuration provides stability for aggressive ramping and rigidity when flute E is completely engaged. • Open structure at the axial end accommodates...

Aprire il catalogo a pagina 2

3 Flute End Mills TOLERANCES (inch) CORNER RADIUS TOLERANCES (inch) R = +.000 / -.002 CORNER RADIUS TOLERANCES (mm) R= +0,00 / -0,05

Aprire il catalogo a pagina 3

Hardness BRINELL Diameter (inch)

Aprire il catalogo a pagina 4

Speed & Feed Recommendations Hardness BRINELL Diameter (inch) * Maximum recommended depth shown * For High Speed Machining with a Radial Width of Cut 5%-7% of D1 please refer for the SGS Website Calculators and Tool Wizard to compensate for chip thinning in the Feed Rate parameters * Finish cuts typically require reduced Feed; also the Radial Width of Cut recommended is not more than 2% x D1 * Reduce Speed & Feed for material harder than listed * Above recommendations are based on ideal conditions; For smaller taper machining centers or less rigid conditions please adjust parameters...

Aprire il catalogo a pagina 5

Hardness BRINELL III . ApxDI AexDI (m/min)

Aprire il catalogo a pagina 6

Speed & Feed Recommendations Hardness BRINELL jAp »A €l Vc ApxDI AexDI (m/min) * Maximum recommended depth shown * For High Speed Machining with a Radial Width of Cut 5%-7% of D1 please refer for the SGS Website Calculators and Tool Wizard to compensate for chip thinning in the Feed Rate parameters * Finish cuts typically require reduced Feed; also the Radial Width of Cut recommended is not more than 2% x D1 * Reduce Speed & Feed for material harder than listed * Above recommendations are based on ideal conditions; For smaller taper machining centers or less rigid conditions please...

Aprire il catalogo a pagina 7

Solid Carbide Tools Performance by Design Solutions Around The Globe SGS Tool Company is a privately-held, ISO-certified leader of round solid carbide cutting tool technology for the aerospace, metalworking, and automotive industries with manufacturing sites in the United States and United Kingdom. Our global network of Sales Representatives, Industrial Distributors, and Agents blanket the world selling into more than 60 countries. Leaders in Solid Carbide Tool Technology Brand names such as Z-Carb, S-Carb, V-Carb, Hi-PerCarb, Multi-Carb have become synonymous with high performance tooling...

Aprire il catalogo a pagina 8Tutti i cataloghi e le schede tecniche SGS FRANCE

-

M155 series

2 Pagine

-

HI-PERCARB® 142P

104 Pagine

-

HI-PERCARB® 143M-S

104 Pagine

-

Z-Carb HPR

16 Pagine

-

PCR

8 Pagine

-

T-Carb

12 Pagine

-

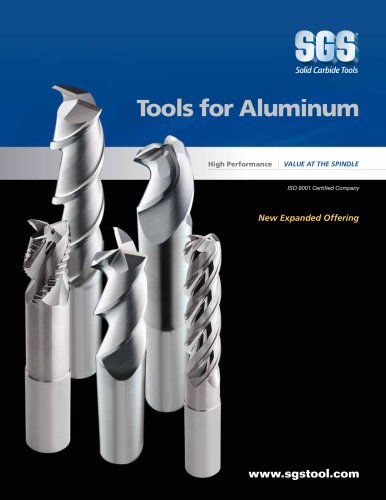

Performance for Aluminum

44 Pagine

-

Composites

20 Pagine

-

High Performance Drills

52 Pagine

-

APR APF

8 Pagine

-

SGS-Speeds-Feeds-Z1

2 Pagine

-

SGS-Speeds-Feeds-7

1 Pagine

-

SGS-Speeds-Feeds-55

2 Pagine

-

2016 Global Product Catalog Metric Tools

240 Pagine

-

multi-carb

12 Pagine