Estratti del catalogo

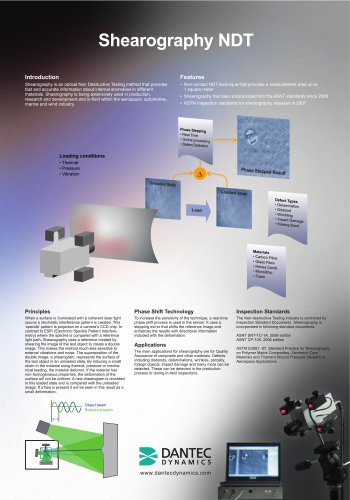

Shearography is an optical Non Destructive Testing method that provides fast and accurate information about internal anomalies in different materials. Shearography is being extensively used in production, research and development and in-field within the aerospace, automotive, marine and wind industry. • Non-contact NDT technique that provides a measurement area up to 1 square meter • Shearography has been incorporated into the ASNT standards since 2006 Defect iypes • Impact Damage • Kissing Bond • Carbon Fibre • Honey Comb Principles When a surface is illuminated with a coherent laser light source a stochastic interference pattern is created. This ‘speckle’ pattern is projected on a camera’s CCD chip. In contrast to ESPI (Electronic Speckle Pattern Interferometry) where the speckle is compared with a reference light path, Shearography uses a reference created by shearing the image of the test object to create a double image. This makes the method much less sensitive to external vibrations and noise. The superposition of the double image, a shearogram, represents the surface of the test object in an unloaded state. By inducing a small strain in the material using thermal, pressure or mechanical loading, the material deforms. If the material has non-homogeneous properties, the deformation of the surface will not be uniform. A new shearogram is recorded in this loaded state and is compared with the unloaded image. If a flaw is present it will be seen in this result as a small deformation. To increase the sensitivity of the technique, a real-time phase shift process is used in the sensor. It uses a stepping mirror that shifts the reference image and enhances the results with directional information included with the deformation. The main applications for shearography are for Quality Assurance of composite and other materials. Defects including disbonds, delaminations, wrinkles, porosity, foreign objects, impact damage and many more can be detected. These can be detected in the production process or during in-field inspections. The Non-destructive Testing industry is controlled by Inspection Standard Documents. Shearography is incorporated in following standard documents: ASNT SNT-TC-1A, 2006 edition ASNT CP-105, 2006 edition ASTM E2581 -07, Standard Practice for Shearography on Polymer Matrix Composites, Sandwich Core Materials and Filament Wound Pressure Vessel's in Aerospace Applicati

Aprire il catalogo a pagina 1Tutti i cataloghi e le schede tecniche Dantec Dynamics

-

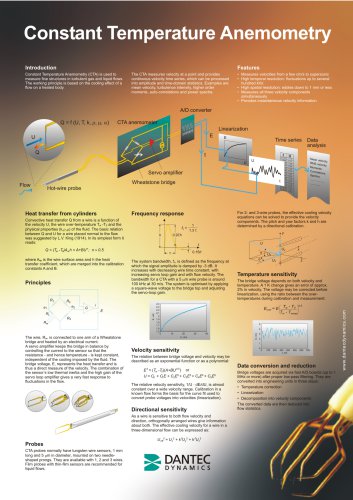

Constant Temperature Anemometry

1 Pagine

-

Particle Image Velocimetry

1 Pagine

-

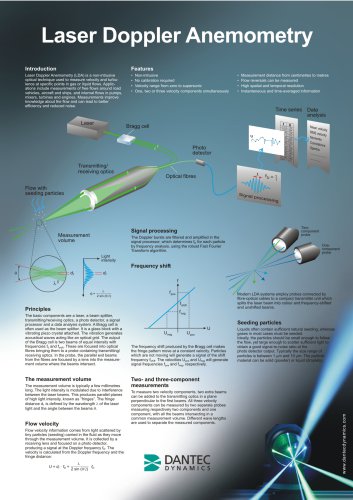

Laser Doppler Anemometry

1 Pagine