Estratti del catalogo

APPING www.conprofecnc.com

Aprire il catalogo a pagina 1

CONverging of Global Resources PROFEssional as Industry Leader

Aprire il catalogo a pagina 2

Tapping tools are extensively used in almost all one machining industries including automotive, aviation & aerospace, electronic consumer, die & mold, machine and tool, general machinery (home hardware/fasteners), power generation, oil & gas, military & national defense, etc.

Aprire il catalogo a pagina 3

03 Machining Application Index Table 11 05-1 Spiral Flute Taps (SFT) 05-2 Spiral Pointed Taps (POT) 07 Customized Tapping Tool Request Form 37

Aprire il catalogo a pagina 5

» Company Profile Conprofe Ultrasonic Green Tool Business Unit (CUGT BU) is committed to providing precision tools and ultrasonic green manufacturing solutions. In the past two decades, we have been adhering to the idea of "CONverging of Global Resources, PROFEssional as Industry Leader", focusing closely on the thread of "green, intelligent and efficient", leading the innovation of processing technology applications by integrating traditional machining with ultrasonic technologies and green technologies, successfully making the breakthrough in hard brittle materials, hard-to-cut metal...

Aprire il catalogo a pagina 6

erging of Global Resources

Aprire il catalogo a pagina 7

» Production Equipment

Aprire il catalogo a pagina 8

*The name of each part of the tap adopts the ISO 13399 standard, an international standard for convenient and efficient data exchange between cutting tools. By using uniform parameters and definitions, tool information exchange between software systems will definitely get easier.

Aprire il catalogo a pagina 9

2. Limit InformationGrade Notes: (D STD: Recommended limit for 6H and class 2 © STD+1: Recommended limit for 1 oversized 6H and class 2 ® STD+2: Recommended limit for 2 oversized 6H and class 2

Aprire il catalogo a pagina 11

Spiral Flute Taps (SFT) Spiral Pointed Taps (POT) Straight Flute Taps (HT) Type • Spiral flute • Spiral point • Straight flute Taps do not produce chips • Stronger style Chips flow out against tapping direction • Strong cutting edges Precise uniformity of tapped thread limit • Lower tapping torque • Pushes chips forward through the hole • High strength of resistance to damage Application First choice for blind holes Recommended for the material giving long chips • First choice for through holes • High speed tapping • For through holes and blind holes • For short chipped material like cast...

Aprire il catalogo a pagina 12

Machining Application Index Table II ulliTAP Application Index Table The cutting speeds (Vc) listed in the respective columns are recommended values which should be adjusted based on specific machining conditions (workpiece material, coolant type, machine type, etc.). - Preferred choice - Alternative choice Note®: Chamfer (TCL): 2.5p means 2.5 times the thread pitch, 5p means 5 times the thread pitch, and so on and so forth. Note©: Thread depth<2TD means the thread depth is less than 2 times the nominal diameter of the thread. Note®: Hole types Tool material-coating Thread depth ® Hole type...

Aprire il catalogo a pagina 13

Selection Guide Spiral Flute Taps (SFT) CDNPRQFE The cutting speeds (Vc) listed in the respective columns are recommended values which should be adjusted based on specific machining conditions (workpiece material, coolant type, machine type, etc.). Preferred choice Alternative choice Chamfer (TCL): 2.5p means 2.5 times the thread pitch, 5p means 5 times the thread pitch, and so on and so forth. Thread depth<2TD means the thread depth is less than 2 times the nominal diameter of the thread. Note®: Hole types Blind hole and through hole Tool material-coating Chamfer (TCL) y Thread depth ®...

Aprire il catalogo a pagina 14

© STD in the Grade column indicates the recommended Limit of the tap. © Spiral flute taps in size larger than M6 have no point. ® The Ordering Code column: • Standard stock item; o Stock inquiry required ® See Page 36 for tap marking style. © The helix angle of spiral flute taps in size M3 and smaller is 40° or above.

Aprire il catalogo a pagina 15

Type Spiral Flute Taps (SFT) Multi-SFT HSSE Multi-SFT-GTS M-Metric coarse thread JIS B4430 Thread tolerance class (TCTR) Thread depthHole typeTool material Surface treatment Chamfer (TCL)Tolerance of shank diameter Rotation direction 6H/JIS2 © STD in the Grade column indicates the recommended Limit of the tap. © Spiral flute taps in size larger than M6 have no point. ® The Ordering Code column: • Standard stock item; o Stock inquiry required © See Page 36 for tap marking style.

Aprire il catalogo a pagina 16

(D STD in the Grade column indicates the recommended Limit of the tap. © Spiral flute taps in size larger than M6 have no point. © The Ordering Code column: • Standard stock item; o Stock inquiry required © See Page 36 for tap marking style. © The helix angle of spiral flute taps in size M3 and smaller is 40° or above.

Aprire il catalogo a pagina 17

CONPROFE Type Spiral Flute Taps (SFT) Multi-SFT MF-Metric fine thread JIS B4430 MF Thread tolerance class (TCTR) Thread depth Hole type Tool material Surface treatment Chamfer (TCL) Tolerance of shank diameter Rotation direction Machining application © STD in the Grade column indicates the recommended Limit of the tap. © Spiral flute taps in size larger than M6 have no point. ® The Ordering Code column: • Standard stock item; o Stock inquiry required © See Page 36 for tap marking style.

Aprire il catalogo a pagina 18

HSSE Type Spiral Flute Taps (SFT) CQNPROFE Multi-SFT Multi-SFT-GTS MF-Metric fine thread JIS B4430 ultiTAP SFT-MF Thread tolerance class (TCTR) Thread depth Hole type Tool material Surface treatment Chamfer (TCL) Tolerance of shank diameter Rotation direction Machining application © STD in the Grade column indicates the recommended Limit of the tap. © Spiral flute taps in size larger than M6 have no point. ® The Ordering Code column: • Standard stock item; o Stock inquiry required © See Page 36 for tap marking style.

Aprire il catalogo a pagina 19

© STD in the Grade column indicates the recommended Limit of the tap. © Spiral flute taps in size larger than 1/4 have no point. ® The Ordering Code column: • Standard stock item; o Stock inquiry required © See Page 36 for tap marking style. © The helix angle of spiral flute taps in size No.6 and smaller is 40° or above.

Aprire il catalogo a pagina 20Tutti i cataloghi e le schede tecniche Conprofe Technology Group Co.

-

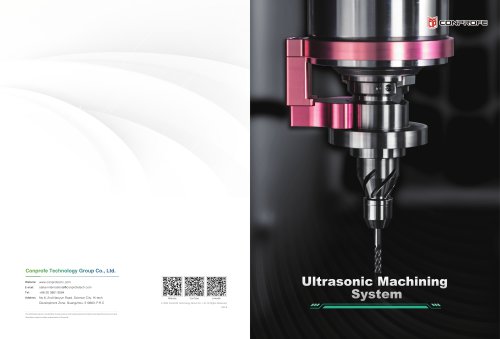

Ultrasonic Machining System

12 Pagine

-

PCD Cutting Tools

14 Pagine

-

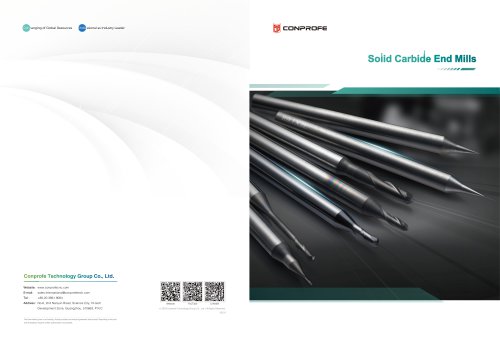

Solid Carbide End Mills

7 Pagine

-

Ultrasonic-Green Machine Tools

119 Pagine