Estratti del catalogo

5 decade of experience 56 countries served 1,987 customers served 1.031 million metric tonnes produced 151 number of grades produced 80,000 tonnes annual melting capacity

Aprire il catalogo a pagina 1

OUR PRESENCE Ambica Steels is one of the most updated stainless steel companies in the world, employing a range of modern steel making technologies. BVCHER STAHL BOHLEK UDDCHOLM Australia ' MA4UA Jfrbl.' South and Latin America Customers Served 137 Countries Served 7 Ambica's presence around the world

Aprire il catalogo a pagina 2

Italy Milan Turkey Izmir ASIA India Customers Served Countries Served Africa Customers Served Countries Served Australia Sydney Europe Customers Served Countries Served Oceania Customers Served Countries Served

Aprire il catalogo a pagina 3

RW TÜV Systems Gmbh, Germany TÜV NORD CERT Gmbh, Germany Approved Manufacturer for Steel Making Year 2015 Loyd’s Register, London, U.K. QUALITY ASSURANCE At the core of the functioning of Ambica Steels, For guaranteeing quality at every step, we lies a strong commitment towards quality. ensure that – Ambica has been progressively innovative since Perfectly documented work-procedures the beginning and its products have stood test endorsed by the 3rd party accreditations, of the time. The organization has a legacy of delivering quality products at desired prices In-house testing laboratories...

Aprire il catalogo a pagina 6

Pressure Equipment Directive 2014/68/EU) Year 2003 Boiler Quality Steel Certification Year 2006 DNV GL Business Assurance India Pvt. Ltd., Chennai RW TÜV Systems Gmbh, Germany RW TÜV Systems Gmbh, Germany Central Boilers Board, India REACH Regulation (EC1907/2006) Year 2013 RW TÜV Systems Gmbh, Germany RW TÜV Systems Gmbh, Germany TÜV NORD CERT Gmbh, Germany TÜV NORD CERT Gmbh, Germany At Ambica, we always study and evaluate our safety systems, and aim to become better than the industry’s best. Magnetic Particle Inspection In order to meet the most demanding product specifications, Ambica...

Aprire il catalogo a pagina 7

MANUFACTURING PROCESS HOT WORKED PRODUCTS Stainless Scraps + Alloys & Virgin Metals Electric Melting Furnace (22MT) AOD Refining (Argon Oxygen Decarburization) Continuous Billets Casting 4 I Ambica Steels Limited I Ingot Casting (Bottom Pouring) Forging Quality Ingots

Aprire il catalogo a pagina 8

Heat Treatment High Speed Peeling V Centreless Grinding V Grit Polishing Cold Drawing Centreless Grinding V Grit Polishing Acid Pickling V Shot Blasting V l Cold Drawing V l Polishing V Acid Pickling

Aprire il catalogo a pagina 9

6 I Ambica Steels Limited I

Aprire il catalogo a pagina 10

I Ambica Steels Limited I

Aprire il catalogo a pagina 11

BRIGHT ROUND BARS With Bright Bar processing facilities of 50,000 tons per year, Ambica is one of the largest producers of cold finished bars in India. Ambica offers high-quality "Improved Machining (IM)” stainless steel bright round bars. The key to improved machinability lies in the special melting process adopted by Ambica, with a greater control upon non-metallic inclusion in the liquid metal.

Aprire il catalogo a pagina 12

I Ambica Steels Limited I

Aprire il catalogo a pagina 13

HEXAGON AND SQUARE BARS Ambica offers very high-quality “Improved Machining (IM)” stainless steel Hexagon and Square bars. Each batch of Squares / Hexagons is heat treated under a very controlled thermometry followed with a rapid quenching process in order to arrive at the most reliable product with an increased consistency in the mechanical properties and a very high machinability. Cold Drawn Hex / Square Bars Hexagon Sizes Square Sizes Size tolerances Available in 30 degrees to 60 degrees through fully automatic both-end chamfering machine (Only in Hexagon bars) Crack Test Magnetic...

Aprire il catalogo a pagina 14

Size tolerances 2 metres - 6 metres (8 to 20 feet) Crack Test Magnetic particle Inspection (MPI) Ultrasonic Test 100% tested through Digital Ultrasonic Flaw Detector, as per ASTM A-388, EN 10308 (class 1 to 4), API 6A/ ISO 10423:2003-PSL 3, SEP 1920:1984 (class A,B,C), MIL STD 2154 Length Tolerance Available in special cut to length bars in tolerance -0/+10 mm (-0/+0.5 inch) Surface Finish HRAP Condition Heat Treatment Solution Annealed, Annealed

Aprire il catalogo a pagina 15

FLAT BARS HRAP Flat Bars Cold Drawn Flat Bars 12 I Ambica Steels Limited I

Aprire il catalogo a pagina 16

Cold Drawn Flat Bars Sizes HRAP Flat Bars

Aprire il catalogo a pagina 17

PRECISION ROUND BARS PUMP SHAFT QUALITY (PSQ) BARS BOAT SHAFT QUALITY (BSQ) BARS Cold worked Precision Bars is one of Ambica’s premium product lines. These super finished precision bars are processed using the ultra-modern combined lines and state of the art equipment. Ultrasonic Inspection and Eddy Current Testing ensures that the bars are free from any internal defects. The bars are then finished using the specially designed finishing machines which ensures that the size tolerances (including the out of roundness) and surface roughness are achieved as desired. 14 I Ambica Steels Limited I

Aprire il catalogo a pagina 18

Size range

Aprire il catalogo a pagina 19

I Ambica Steels Limited I

Aprire il catalogo a pagina 21

HOT ROLLED BARSAmbica's Hot rolled bars are a perfect solution for all forging applications like close die forging and open die forging. Hot Rolled bars sizes 18 I Ambica Steels Limited I

Aprire il catalogo a pagina 22

I Ambica Steels Limited I

Aprire il catalogo a pagina 23

20 I Ambica Steels Limited I

Aprire il catalogo a pagina 24

Ambica is the Largest producer of Duplex Stainless Steel Long Products in India. Ambica produces these materials for a wide variety of applications and industrial sectors. These user segments are the benchmark for quality. Every piece is continually and stringently checked for quality and certified. Ambica's steels are melted, casted and formed with perfection and care. Due to its two-phase microstructure, Duplex steels are extremely tough to produce. It took Ambica many years of continuous trials and errors, before gaining a complete control over this grade. The dual phase structure...

Aprire il catalogo a pagina 26

I Ambica Steels Limited I 23

Aprire il catalogo a pagina 27

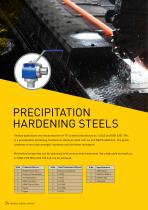

PRECIPITATION HARDENING STEELS Ambica specializes into the production of 17-4 steels (also known as 1.4542 and AISI 630). This is a precipitation hardening martensitic stainless steel with Cu and Nb/Cb additions. The grade combines a very high strength, hardness and corrosion resistance. Mechanical properties can be optimized with various heat treatments. Very high yield strength up to 1000-1100 MPa (145-160 ksi) can be achieved. 24 I Ambica Steels Limited I

Aprire il catalogo a pagina 28