Katalogauszüge

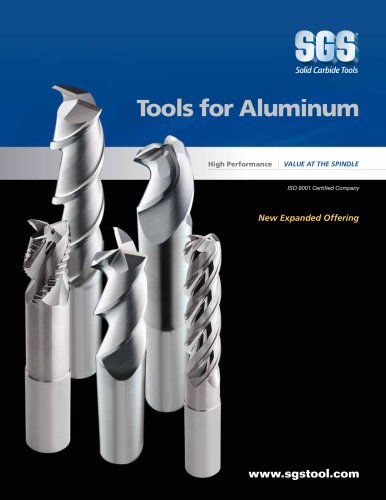

Solid Carbide Tools Tools for Aluminum High Performance VALUE AT THE SPINDLE ISO 9001 Certified Company

Katalog auf Seite 1 öffnen

The original, symmetrical flute design features an engineered flute form that provides high performance results through a full range of machining conditions. These tools are designed for aggressive aluminum, non-ferrous, and non-metallic machining requiring a high level of material removal. Engineered Flute Design • Effective chip removal at high feed rates • Lower cutting forces than comparable products • Improved balance at high spindle speeds • Improved workpiece finish through better balance • More effective plunging vs. conventional designs Various Reach, Neck and End Options...

Katalog auf Seite 2 öffnen

Maximum RPM Capability Results of Independent Lab Balance Analysis Testing per the ISO G2.5 Tolerance ½” Diameter Tools Equal Flute Lengths and Overall Lengths Available with TiB2 Coating (Titanium Diboride). SGS S-Carb Series 43 Design This ceramic based coating ensures a smooth surface and a low affinity to cold welding or edge build-up, which makes it optimal for aluminum and copper 2 Flute Aluminum Design applications. It has high toughness and high hardness. Coefficient of Friction: 0.45 Thickness: 1 - 2 Microns (based on tool diameter) S-Carb High Performance End Mills are ideal for...

Katalog auf Seite 3 öffnen

CORNER RADiUS TOLERANCES (inch) R = +0.0000 / -0.0020 (continued on next page)

Katalog auf Seite 9 öffnen

CORNER RADiUS TOLERANCES (inch) R = +0.0000 / -0.0020 (continued on next page)

Katalog auf Seite 10 öffnen

CORNER RADiUS TOLERANCES (inch) R = +0.0000 / -0.0020

Katalog auf Seite 11 öffnen

CORNER RADiUS TOLERANCES (inch) R = +0.0000 / -0.0020 (continued on next page)

Katalog auf Seite 13 öffnen

CORNER RADiUS TOLERANCES (inch) R = +0.0000 / -0.0020

Katalog auf Seite 14 öffnen

CORNER RADiUS TOLERANCES (inch) R = +0.0000 / -0.0020

Katalog auf Seite 15 öffnen

Series 43B S-Carb - 3 Flute TOLERANCES (inch) DiAMETER D1 D2

Katalog auf Seite 16 öffnen

CORNER RADiUS TOLERANCES (mm) R = +0,00 / -0,05

Katalog auf Seite 19 öffnen

Series 43M S-Carb – 3 Flute Polished L1 New Expanded Tools Cutting Diameter D1 Polished Flute

Katalog auf Seite 20 öffnen

New Expanded Tools length of Cut L2

Katalog auf Seite 21 öffnen

CORNER RADiUS TOLERANCES (mm) R = +0,00 / -0,05

Katalog auf Seite 22 öffnen

New Expanded Tools SERiES 43MB (METRiC)

Katalog auf Seite 23 öffnen

High PERFORMANCE s-CARB CHIP BREAKER Roughing End Mills The original, symmetrical 3-flute design features an engineered flute form that provides high performance results through a full range of machining conditions. This expanded offering includes a variety of standard, reach, and corner radius options that are available with exclusive Ti-NAMITE-B coating for improved tool life. Value at the Spindle design and engineering ensure outstanding performance in a variety of aluminum applications.

Katalog auf Seite 24 öffnen

Series 43CB & 43MCB For Aluminum, Non-Ferrous, & Non-Metallic Materials Symmetrical End Gashing: Superior balance in a high-speed environment reduces vibration and increases plunging capabilities compared to traditional 3-flute designs Engineered Flute Design: Unique flute shape facilitates the rapid movement of the large volume of chips created during aggressive machining Specialized Chip Breaker: The chip breaker disrupts the chip flow along the cutting edge, resulting in smaller and more controlled chips, while preventing material build-up between the cutting edge and tool • nique...

Katalog auf Seite 25 öffnen

Series 43CB | S-Carb Chip Breaker - 3 Flute DiAMETER CORNER RADiUS TOLERANCES (inch) R = +0.0000 / -0.0020

Katalog auf Seite 26 öffnen

CORNER RADiUS TOLERANCES (inch) R = +0.0000 / -0.0020

Katalog auf Seite 27 öffnen

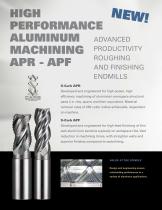

ADVANCED PRODUCTIVITY ROUGHING AND FINISHING ENDMILLS S-Carb APR Developed and engineered for high power, high efficiency machining of aluminium aerospace structural parts (i.e. ribs, spars) and their equivalent. Material removal rates of 550 cubic inches achievable, dependent on machine. S-Carb APF Developed and engineered for high-feed finishing of thin wall aluminium sections typically on aerospace ribs. Vast reduction in machining times, with straighter walls and superior finishes compared to waterlining. VALUE AT THE SPINDLE Design and engineering ensure outstanding performance in...

Katalog auf Seite 28 öffnen

APR S-CARB APR • flute design for high feed 3 power roughing • High feed direct plunge ability • Through coolant design • olished flute design to P maximize chip evacuation • 4 flute unique variable geometry reduces vibration and allows finishing of thin walls in one pass • Through coolant design • Polished flutes for superior finishes • ignificant reduction S in cycle times Typical Method: High-speed waterline finishing, multiple passes at numerous levels to produce acceptable thin walls APF Method: High speed finishing at full depth without wall distortion 'One Hit' Flute Design...

Katalog auf Seite 29 öffnen

Series 43APR S-Carb – 3 Flute Corner Radius Tolerances (inch) R= +/– 0.0018 Available on request: • JetStream Technology • Side exits for MQL application

Katalog auf Seite 30 öffnen

CORNER RADiUS TOLERANCES (mm) R = +/- 0,03 JetStream Technology • side exits for MQL applications

Katalog auf Seite 31 öffnen

Series 43APF S-Carb – 4 Flute Corner Radius Tolerances (inch) R= +/– 0.0018 Available on request: • JetStream Technology

Katalog auf Seite 32 öffnen

CORNER RADiUS TOLERANCES (mm) R = +/- 0,03 Available on request: • JetStream Technology

Katalog auf Seite 33 öffnen

SKI-CARB END MILLS FOR NON-FERROUS, ALUMINUM, & NON-METALLIC APPLICATIONS Design Features: Varied Speed and Feed • Circular Land reduces edge aggressiveness for varied speed and feed rates and allows for milling into corners while significantly reducing chatter. Superior Chip Control • Ski Land with primary and secondary flute wall construction minimizes chip interference by directing chips away from secondary flute. Optimal Rake • High Helix (45 degree) increases effective rake for greater shearing ability without reducing edge strength. Outstanding Rigidity • Short Length increases...

Katalog auf Seite 34 öffnen

Slotting in 6061 - T6 Aluminum 1/2” Diameter - .300” Ad 8% Flood Coolant Tool Life in Feet 1,400 0 Wear Comparison A390 Cast Aluminum Ski-Carb Wear Comparison A390 Cast Aluminum 10,000 rpm / 120 ipm .100 Rw x .300 Ad Wear (inch) 33% less wear with Ti-NAMITE-B after 400” of Machining Ti-NAMITE-B Wear (inch) 33% less wear with Ti-NAMITE-B after 400” of Machining Ti-NAMITE-B is an advanced coating developed specifically for the high performance machining of Aluminum and its alloys. Ti-NAMITE-B offers the following benefits: • ow affinity to Aluminum L helps to prevent edge build-up • igh level...

Katalog auf Seite 35 öffnenAlle Kataloge und technischen Broschüren von SGS FRANCE

-

M155 series

2 Seiten

-

HI-PERCARB® 142P

104 Seiten

-

HI-PERCARB® 143M-S

104 Seiten

-

Z-Carb HPR

16 Seiten

-

PCR

8 Seiten

-

T-Carb

12 Seiten

-

Series 33

8 Seiten

-

Composites

20 Seiten

-

High Performance Drills

52 Seiten

-

APR APF

8 Seiten

-

SGS-Speeds-Feeds-Z1

2 Seiten

-

SGS-Speeds-Feeds-7

1 Seiten

-

SGS-Speeds-Feeds-55

2 Seiten

-

2016 Global Product Catalog Metric Tools

240 Seiten

-

multi-carb

12 Seiten