Katalogauszüge

SANDVIK ROCK DRILL STEEL DEVELOPED FOR TOMORROW’S REQUIREMENTS For more information and contact: MATERIALS.SANDVIK/ROCKDRILLSTEEL

Katalog auf Seite 1 öffnen

THE DEMANDS ON DRILL RODS ARE GROWING The demands on drill rods are continuously growing in line with the automation and productivity focus in the mining industry. You just have to be able to rely on the equipment. Close tolerances, high fatigue strength and toughness along with elevated esistance to wear and permanent distortion r just form one side of the coin. Cost control, inimized stock m and reliable deliveries make up the other side. Sandvik is leading this development together with our customers. We have been producing long-lasting bars with straight holes, uniform wall-thickness...

Katalog auf Seite 2 öffnen

steel with good response to surface induction hardening and suitable for carburizing. High fatigue strength and wear resistance in the case-hardened condition. Sanbar® 61 - Tapered rods High strength silicon steel with good toughness and impact resistance. Sanbar® 64 - Extension and shank rods Air-hardening, high nickel alloy steel with excellent fatigue strength and wear resistance, and good response to carburizing. GRADES AND APPLICATIONS Sandvik rock drill steel is available in four standard grades that are described in detail in the enclosed product sheets. We are also tailoring...

Katalog auf Seite 3 öffnen

DEDICATED PRODUCTION FROM STEEL MELT TO FINISHED PRODUCT As one of very few drill steel rod manufacturers in the world, our manufacturing is fully integrated, from teel melt s to final rods. This means that we control the quality from start to finish. In addition, our rock drill steel mill is fully automated and entirely dedicated to rock drill steel. RESEARCH AND DEVELOPMENT Every year, Sandvik invests heavily in research and d evelopment of properties and performance of our steels. This is the backbone of the Sandvik success, nd a it shows in efficient production processes, ptimized o...

Katalog auf Seite 4 öffnenAlle Kataloge und technischen Broschüren von SANDVIK MATERIALS TECHNOLOGY

-

STAINLESS STEELS FOR MACHINING

29 Seiten

-

AquaSan Ni50

2 Seiten

-

APM 9980

4 Seiten

-

APM 2723

5 Seiten

-

APM 2377, UNS S31803

4 Seiten

-

APM 2354, UNS S31603

3 Seiten

-

APM 2327, UNS S32505

4 Seiten

-

Sandvik precision strip steel

16 Seiten

-

SANMAC 4571

10 Seiten

-

Sandvik billets and blooms

10 Seiten

-

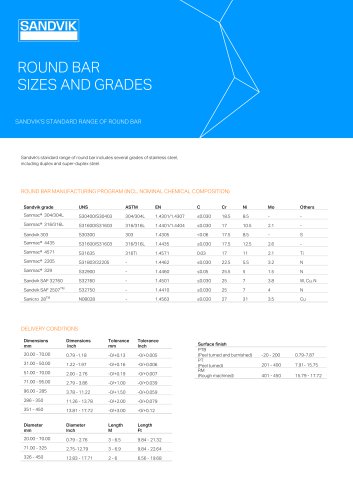

ROUND BAR SIZES AND GRADES

4 Seiten

-

Sanmac®329

2 Seiten