Katalogauszüge

M a x i m u m P r e s s u r e. High Pressure Technology • Testing Equipment Hydraulics • Pneumatics Liquified Gas Pumps LGP Serie

Katalog auf Seite 1 öffnen

Content / About Maximator Content: Seite: About MAXIMATOR 2 Anwendung und Funktion 3 Einsatz für entzündliche Fluide 4 Produktübersicht 5 MLGP Serie 6 – 7 SLGP Serie 8 – 9 GLGP Serie 10 – 11 Kältemittelübersicht 12 – 13 Weitere Leistungen - Hydraulik und Pneumatik 14 - Hochdrucktechnik und Prüftechnik 15 At your side, everywhere As an internationally leading company specialising in high-pressure technology, MAXIMATOR develops high-performance air driven liquid pumps and gas boosters for a variety of uses and applications. For decades we have supported well-known companies in the automotive...

Katalog auf Seite 2 öffnen

Application and Function Liquified Gas Pumps – the Maximator-Concept The Maximator LGP (Liquified Gas Pump) series was developed for use with refrigerants. The design of these pumps is based on the mode of operation of gas compressors in combination with proven highpressure pump technology. The technology has been optimized for the compression of liquid and gaseous fluids, so that the pumps of the LGP series can compress and convey both aggregate states. The SLGP and GLGP pumps are also optionally available with reduced stroke. On the one hand, this reduces the size of the pump and, on the...

Katalog auf Seite 3 öffnen

Selecting the right pump The following parameters are required for designing and selecting pumps: » Required operating pressure Desired pump capacity at operating pressure Available air drive pressure Fluid, Temperature of the fluid Ambient Temperature Information on requirements regarding size, weight, etc. Desired options and sealing materials Note: On request, the Maximator team will undertake the design and advise on the selection. There are special requirements for many applications; advice from experienced Maximator staff is therefore recommended. Versions & Options* Common...

Katalog auf Seite 4 öffnen

Product overview Flame arrester* available sealing materials** CR EPDM FFKM PTFE FKM HNBR standard * the flame arrester cannot be retrofitted. **The sealing material used in the standard can be found in the product name. Note: further technical information is available on the product data sheets. Sealing materials NBR – Nitrile rubber,good cold and deformation behavior at -30°C to 100°C, media compatibility: low, elastic. HNBR – hydrogenated nitrile rubber, good temperature behavior at -40°C to 140°C, media compatibility: low, abrasion resistant. EPDM – Ethylene propylene rubber, good...

Katalog auf Seite 5 öffnen

MLGP 7-NBR » Single-acting » With one air drive piston » Operating pressures of up to 70 bar (1.015 psi) » Formula for gas outlet pressure: pb = i * pl The compact and robust pumps of the MLGP series are available in a wide range of options to compress a broad spectrum of refrigerants. • Material: Pump heads made of aluminium, Pistons and valves made of stainless steel and NBR Sealing in standard • Standard models with bottom inlet • Suitable for air drive pressures from 1 to 10 bar (14.5 to 145 psi) • Seal version, e.g. FKM, HNBR, EPDM, CR for special fluids Order code: see media...

Katalog auf Seite 6 öffnen

Performance Graph for gaseous state • LTA-Option:Low-temperature modification for the high pressure and air drive section (-40°C bis 60°C) Order code: MLGP7 - LTA Drive pressure pL = 6 bar, Test fluid: Nitrogen, pA = gas inlet pressure Flow (lN/min) • LT-Option:Low-temperature modification for the high pressure section (-40°C up to 60°C) Order code: MLGP7 - LT Other options available on request. Performance Graph for liquid state Drive pressure = pL, Test fluid: Water-Oil-Emulsion approx. 1 - 10 cst 60 Flow (l/min

Katalog auf Seite 7 öffnen

SLGP 3-NBR » Double-acting » Single stage » With one air drive piston » Operating pressures of up to 52 bar (755 psi) » Formula for gas outlet pressure: pb = i * pl + pa The compact and robust pumps of the SLGP series are available in a wide range of options to compress a broad spectrum of refrigerants. • Material: Pump heads made of aluminium, Pistons and valves made of stainless steel and NBR Sealing in standard • Standard models with bottom inlet • Suitable for air drive pressures from 1 to 10 bar (14.5 to 145 psi) • Seal version, e.g. FKM, HNBR, EPDM, CR for special fluids - Order code:...

Katalog auf Seite 8 öffnen

SLGP 3-3-NBR » Double-acting » Two stage » With one air drive piston » Operating pressures of up to 52 bar (755 psi) » Formula for gas outlet pressure: pB = 3,4 * pL + 3,4/3,2 * pA Performance Graph SLGP 3* for gaseous state • FEC-Option: for dry compressed air or Drive pressure pL = 6 bar, Test fluid: Nitrogen, pA = gas inlet pressure nitrogen drive Order code: SLGP3 - FEC • LTA-Option:Low-temperature modification for the high pressure and air drive section (-40°C bis 60°C) Order code: SLGP3 - LTA Flow (lN/min) • LT-Option:Low-temperature modification for the high pressure section (-40°C...

Katalog auf Seite 9 öffnen

GLGP 5-NBR » Double-acting » Single stage » With one air drive piston » Operating pressures of up to 90 bar (1.305 psi) » Formula for gas outlet pressure: pb = i * pl + pa The compact and robust pumps of the GLGP series are available in a wide range of options to compress a broad spectrum of refrigerants. • Material: Pump heads made of aluminium, Pistons and valves made of stainless steel and NBR Sealing in standard • Standard models with bottom inlet • Suitable for air drive pressures from 1 to 10 bar (14.5 to 145 psi) • Seal version, e.g. FKM, HNBR, EPDM, CR for special fluids - Order...

Katalog auf Seite 10 öffnen

GLGP 5-5-NBR » Double-acting » Two stage » With one air drive piston » Operating pressures of up to 90 bar (1.305 psi) » Formula for gas outlet pressure: pB = 5,6 * pL + 5,6/5,2 * pA Performance Graph GLGP 5* for gaseous state • FEC-Option: for dry compressed air or Drive pressure pL = 6 bar, Test fluid: Nitrogen, pA = gas inlet pressure nitrogen drive Order code: GLGP 5 - FEC • LTA-Option:Low-temperature modification for the high pressure and air drive section (-40°C bis 60°C) Order code: GLGP 5 - LTA Flow (lN/min) • LT-Option:Low-temperature modification for the high pressure section...

Katalog auf Seite 11 öffnenAlle Kataloge und technischen Broschüren von Maximator GmbH

-

Maximator Imagebroschüre

24 Seiten

-

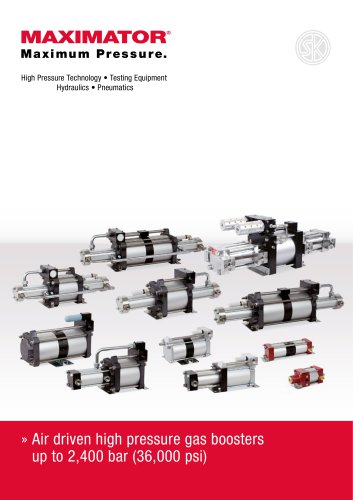

Gas Booster and Air Amplifier

56 Seiten

-

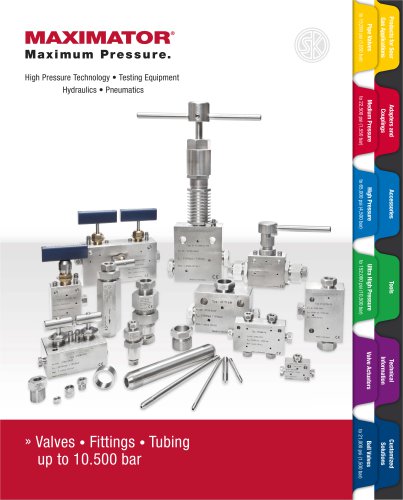

Valves-Fittings-and-Tubings

175 Seiten

-

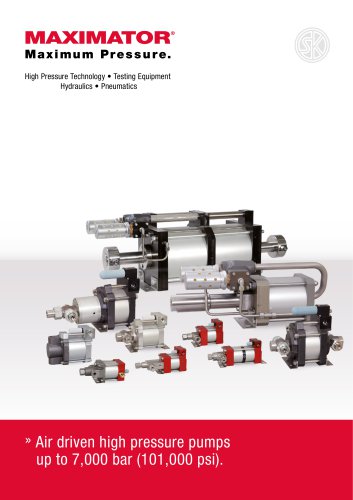

High-Pressure-Pumps

40 Seiten

Archivierte Kataloge

-

Behaelterprueftechnik

4 Seiten

-

Maximator-Rental-Units

28 Seiten

-

MAXIMATOR Gas Seals

4 Seiten

-

Maximator Proportional Valve

7 Seiten

-

MX-Compressors

24 Seiten

-

Oil and Gas Technology

24 Seiten

-

MAXIMATOR-Gas-and-Water-Injection-

24 Seiten

-

MAXIMATOR Valves Fittings Tubing

168 Seiten

-

MAXIMATOR Gas Boosters

32 Seiten

-

Air Amplifier Stations

12 Seiten