Katalogauszüge

We offer: Precision and a diversity of services. For nearly 100 years. Made in Germany.

Katalog auf Seite 1 öffnen

1920 Foundation of Prazisions-Werkzeugfabrik Nurnberg-Lauf Moschkau & Glimpel by Richard Glimpel 1933 Registration of brand name EMUGE (acronym of German phonetic spelling “M u G” for “Moschkau und Glimpel”) 1950 Acquisition of production and sales license of “Spieth” clamping system 1920 Single-finishing tap with spiral point EMUGE 1953 Tap with steep spiral flutes Clamping of workpiece TiN-coated taps with buttress thread 2005 InnoForm cold-forming taps MILESTONES The development of our company. What sets us apart from other companies? It is our knowledge of how to combine individual...

Katalog auf Seite 2 öffnen

Helmut Glimpel, the current owner and managing director joins the company Speedsynchro® Modular collet holder Acquisition of company FRANKEN, Rückersdorf Circle segment end mills Punch Tap oval form threading technology Completion of the new EMUGE company building Two generations of the entrepreneurial family Glimpel: (LTR) Cornelia Glimpel-Pompe, Thomas Pompe, Helmut Glimpel, Gerhard Knienieder and Ulrike Glimpel-Knienieder Since our foundation in the city of Lauf an der Pegnitz in 1920 we have been committed to precision and innovation. For almost 100 years EMUGE-FRANKEN has consistently...

Katalog auf Seite 3 öffnen

© Image source: HERMLE AG PARTNER OF NUMEROUS INDUSTRIES We complement each other: T hat is why we are a perfect match. Our objective is to optimise your production processes thus improving efficiency – in d ifferent industrial sectors from mechanical engineering to medical technology. Achieving this objective is the focus of our research and development. Our performance is based on a wide variety of skills and experiences of our experts as well as on state-of-the-art production methods and a comprehensive quality assurance. In addi tion to our standard range of over 40.000 stock items, we...

Katalog auf Seite 4 öffnen

“The cooperation with EMUGE-FRANKEN enables our customers to benefit from a wide variety of individual solutions. They have access to the supply of system solutions and high-quality precision products Reinhard Meier | Technical Service

Katalog auf Seite 5 öffnen

“We offer a diverse range of standard tools as well as customer specific products. With this approach we are able to offer taps which are perfectly adapted to various applications.” Christian Dörfler | Thread Grinding Division

Katalog auf Seite 6 öffnen

THREAD CUTTING TECHNOLOGY We have the experience. You can create high-quality internal threads with our taps and cold-forming taps. We provide these tools for all common thread systems in a wide variety of dimensions. Our tools are suitable for a broad range of materials thanks to their well-matched cutting geometries and surface treatments. Our twist drills provide an excellent drill hole quality and they are a perfect match to our threading tools. Accurate centering characteristics and an optimised cutting behaviour provide the best possible efficiency and productivity. We offer you a...

Katalog auf Seite 7 öffnen

THREAD CUTTING TECHNOLOGY We have the foresight. The technologies of thread production continue to undergo constant development. For example, thread milling can be a useful alternative to thread cutting or cold forming of threads. A broad range of thread milling cutters from a simple thread mill for the production of internal and external threads to a circular drill thread mill are available. Consistently committed to innovation, we scrutinised and rethought existing methods and together with a partner in the automotive industry we developed new motions for thread production. Our Punch Tap...

Katalog auf Seite 8 öffnen

“Shortening the tool path and reduction of the main machining time are only two of many additional arguments in favour of our innovative Punch Tap production technology.” Johannes Nold and Marko Übler | Tool Design

Katalog auf Seite 9 öffnen

“As an accredited calibration service provider we put special emphasis on accurate gauging and documentation of the different measuring equipment for our customers.” Siegfried Göbel | DECOM UGK

Katalog auf Seite 10 öffnen

THREAD GAUGING TECHNOLOGY Our thread gauges enable you to organise your production processes in a safe and therefore economically efficient way. Any dimensional and form deviations as well as worn or u nusable threads can be recognised at an early stage. Gauges made from special gauge steel are available ex stock for a large number of thread systems and tolerance ranges for all practical applications. In addition, we also manufacture thread gauges to individual specifications. Our cooperation partner DECOM UGK located on the EMUGE premises is available for the calibration of your gauging...

Katalog auf Seite 11 öffnen

TOOL CLAMPING TECHNOLOGY Optimal solutions f or rapid tool change. Our complete programme of quick-change and collet holders for threading tools offers you numerous options, such as minimum length compensation for improved quality of thread and tool life, minimum quantity lubrication provides cost advantages. An integrated transmission gear provides significant time and energy saving, leading to an increased use in series production. A wide range of clamping tools is available for the accurate clamping of milling cutters and drills. They provide extremely high precision with tight...

Katalog auf Seite 12 öffnen

“The Speedsynchro® Modular enables our customers to significantly reduce cycle time and energy. As a result the economic efficiency in thread production increases.” Thomas Berschneider | Research and Development

Katalog auf Seite 13 öffnen

“The μ-accurate clamping of your workpieces is the result of a precise analysis of your production process and our detailed planning phase.” Roland Meyer | Clamping Tools Assembly

Katalog auf Seite 14 öffnen

TOOL CLAMPING TECHNOLOGY W e develop bespoke c lamping devices. If you require your workpieces clamping μ-accurate with high repeat precision we are your ideal partner. We can offer bespoke clamping tools to meet your precise application r equirements, taking into account all conditions such as machine connection, machining process or your desired accuracy. We have extensive experience in customised clamping tools, this results in clamping d evices specifically adapted to your machining processes which will reduce production costs and provide optimal results.

Katalog auf Seite 15 öffnenAlle Kataloge und technischen Broschüren von EMUGE-Werk Richard Glimpel GmbH & Co. KG

-

FIBER-cut

28 Seiten

-

Hybrid Additive Manufacturing

12 Seiten

-

End Mills for Trochoidal Machining

12 Seiten

-

Expert

32 Seiten

-

Turbine

52 Seiten

-

TiNox-Cut

40 Seiten

-

ZGF

24 Seiten

-

Catalogue 250

440 Seiten

-

Catalogue 156

92 Seiten

-

NAWA

12 Seiten

-

NAWA Modular

4 Seiten

-

Catalogue 154

104 Seiten

-

Catalogue 150

872 Seiten

-

CATALOG 520

672 Seiten

-

Precision Clamping Catalogue 135

224 Seiten

-

Aerospace

20 Seiten

-

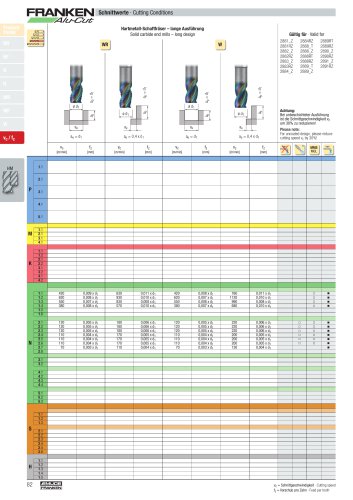

Cutting Conditions

1 Seiten