Catalog excerpts

Control line Manufacturing Range The Oil & Gas sector represents one of Fine Tubes principal markets for supply of a wide range of tubular product forms and materials. Our products have been successfully used in some of the most aggressive subsea and downhole conditions and we have a long proven track record of supplying products that meet the strict quality requirements of the Oil & Gas and geothermal energy sectors. Coiled tubing is available in a range of different product forms depending on the customer requirements. We manufacture seam welded and redrawn, seam welded and floating plug redrawn and seamless tube products. The standard grades are 316L, alloy 825 and alloy 625. Other grades of stainless steel in duplex and superduplex and nickel alloy are available on request. Tubing can be supplied in the annealed or cold worked condition. Improvements in the technology for the enhanced exploitation of oil and gas fields has increasingly required the use of long continuous lengths of stainless steel and nickel alloy tubulars for hydraulic control, instrumentation, chemical injection, umbilical and flowline control applications. The benefits of this tubular technology have resulted in reduced operating costs, improved recovery methods and reduced capital expenditure by connecting downhole valves and chemical injection with remote and satellite wells to a fixed or floating central operating platform. Applications Fine Tubes offers coiled control line in stainless steel and nickel alloys. Our products are used in the following applications: • • • • Downhole hydraulic control lines. Downhole chemical control lines. Subsea control lines for hydraulic power and chemical injection. Smoothbore control lines used in fibre optic applications. • Welded and drawn tubing. • Welded and floating plug drawn tubing. • Diameter from 3mm (0.118”) to 25.4mm (1.00”) OD. • Wall thickness from 0.5mm (0.020”) to 3mm (0.118”). • OD tolerance +/- 0.005” (0.13mm) and +/- 10% wall thickness. Other tolerances are available on request. • Coil lengths up to 1500m (5,000ft) without orbital joints depending on product dimensions. • Coil lengths up to 13,500m (45,000ft) with orbital joints. • Encapsulated, PVC coated or bare line tubing. • Available on wooden or steel drums. Production Facilities • Cold pilger mills • Cold draw benches • Tube welding mills - In-line weld mills • Controlled atmosphere heat treatment • Pickling & passivation plant • NDT ultrasonic & eddy current testing • Hydrostatic testing • Radiographic examination www.finetubes.com Disclaimer: The information contained within this data sheet is for guidance only and is not intended for warrant

Open the catalog to page 1

Control line Control Line Product Forms Types of tubing Long coils of tubing can be manufactured in four main forms: • Seamless – in which a billet of metal is extruded into a tube and drawn to final size. • Welded* – made by forming a strip of material into a tube and welding the seam. Some local cold work on the weld may also be applied by calibrating rolls. • Welded & Sunk – after being welded the tube is drawn through a die to homogenise the seam weld. • Welded & Floating Plug Drawn – after being welded the tube is drawn through a die with a floating plug in the bore to rework the weld...

Open the catalog to page 2

Control line Advantages of Redrawing Welded Tube Control Line Pressure Calculations Long lengths can be made by seam welding formed strip but such tubing has OD & ID discontinuity and may suffer from local problems of mechanical strength or corrosion. A welded & sunk tube improves these aspects and has been proven reliable in service over several decades for offshore applications. Although more expensive than welded only tubing, the welded and redrawn tube is still relatively inexpensive compared to seamless. The working pressure for a tube depends on the operating conditions of each...

Open the catalog to page 3

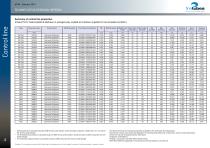

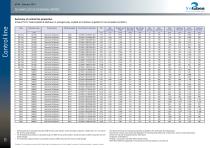

finefiriaes www.finetubes.com Summary of control line properties. Product form: Seamwelded & Redrawn is autogenously welded and redrawn supplied in the annealed condition. The General chemical and mechanical properties are applied to the coiled tube where appropriate. Note the part numbers used include the designation for including orbital weld joints. All joints are x-rayed in at least three planes. Control line may also be supplied without orbital joints. Certification to EN10204 3.1 Certified in accordance with NACE MR 0175/ISO15156:3 ASTM B444 & B423 as applicable to mechanical and...

Open the catalog to page 4

finefiriaes www.finetubes.com Summary of control line properties. Product form: Seamwelded & Redrawn is autogenously welded and redrawn supplied in the annealed condition. The General chemical and mechanical properties are applied to the coiled tube where appropriate. Note the part numbers used include the designation for including orbital weld joints. All joints are x-rayed in at least three planes. Control line may also be supplied without orbital joints. Certification to EN10204 3.1 Certified in accordance with NACE MR 0175/ISO15156:3 ASTM B444 & B423 as applicable to mechanical and...

Open the catalog to page 5

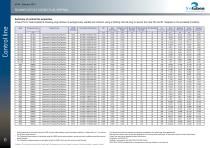

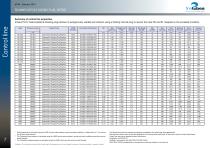

finefiriaes www.finetubes.com Summary of control line properties. Product form: Seamwelded & Floating plug redrawn is autogenously welded and redrawn using a floating internal plug to rework the tube OD and ID. Supplied in the annealed condition. * Working pressure is calculated using the LAME formula under ambient, neutral and static conditions. A safety factor of 1.6 is used on the minimum yield pressure. ** The Theoretical burst pressure is calculated using the LAME formula under ambient, neutral and static conditions using the minimum tensile strength. A The Theoretical collapse...

Open the catalog to page 6

finefiriaes www.finetubes.com Summary of control line properties. Product form: Seamwelded & Floating plug redrawn is autogenously welded and redrawn using a floating internal plug to rework the tube OD and ID. Supplied in the annealed condition. * Working pressure is calculated using the LAME formula under ambient, neutral and static conditions. A safety factor of 1.6 is used on the minimum yield pressure. ** The Theoretical burst pressure is calculated using the LAME formula under ambient, neutral and static conditions using the minimum tensile strength. A The Theoretical collapse...

Open the catalog to page 7All FINE TUBES LTD. AND SUPERIOR TUBE CO. catalogs and technical brochures

-

Oil & Gas Previous Projects

4 Pages

-

Oil & Gas

8 Pages

-

Medical

8 Pages

-

ENERGY

8 Pages

-

Chemical process

4 Pages

-

HPLC

2 Pages

-

Alloy Ti 3AI/2.5V

1 Pages

-

Nickel Alloy Alloy C22

1 Pages

-

Super Duplex 2507

1 Pages

-

Alloys 304 / 304L

1 Pages